Papers

IASS - Beyond the limits of man

Rigidized Inflatable Structures: A production method for optimized structures

.

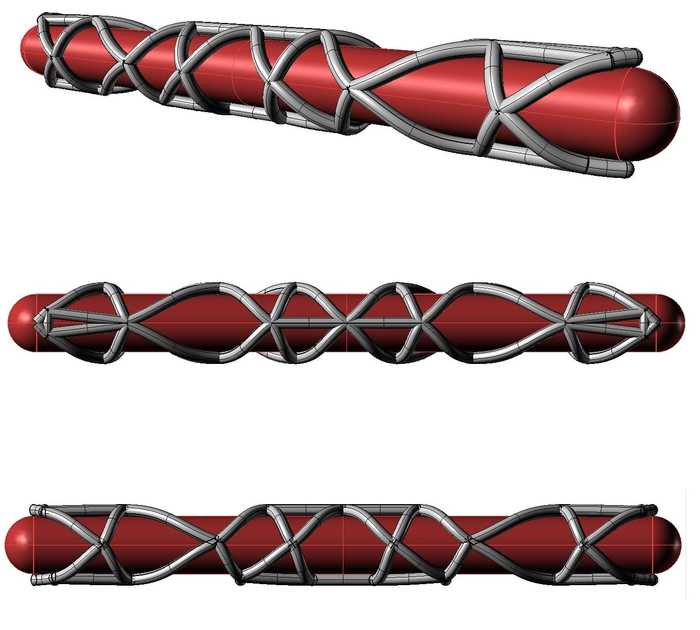

The topological optimization is focused on the reduction of material. A reduction of 40% in material whilst maintaining stiffness properties can be achieved with generative design tools that will reduce redundant material. In fact a section-active structure as defined by Engel is topologically optimized. In all the cases a section-active beam will transfer to a vector-active structure with bending-stiff connections. We used a generative design tool for size and shape optimization: the ParaGen method by Dr.-Ing Peter von Buelow at the University of Michigan. The case studies in Solidthinking Inspire 9.0 show that the morphology and topology of a structurally optimized one-bay beam (Figure 01) are the basis for structurally optimized section-active structure systems, under the same conditions and same constraints.

Figure 01

Morphology and topology are strongly related to type, number and place of supports, and the type and position of loads used. Material, volume fraction and the strength of the force(s) do not determine the topology but influence component attributes that mostly deal with size and shape optimization.

Current production methods and processes are not fully adequate for producing elements whose doubly curved shape is derived from a structural optimization analysis 3 as mentioned above. For example, the latest experiments on rapid manufacturing of buildings structures 4 are encouraging, but show how difficult this construction technique can be applied for full buildings. The best results have been achieved with mechanically pre-stressed fabric formwork. But despite the achievements, the method can be complicated and in many cases a large amount of additional falsework is needed 5. Because of its nature to conform to funicular shapes, a production method based on inflatable membranes used as a mould which subsequently is rigidized, is believed to be a promising solution. In that case the formwork of the three-dimensional structure consists of inflatables and is entirely based on form-active principles.

Figure 02

The rigidization mechanisms with polymere composites developed over the last 50 years including advanced mechanisms for use in space engineering is impressive. Cardogan et al.6 comes to the following mechanisms: 1. Thermally cured thermoset composites, 2. Ultra-violet cured composites, 3. Plasticizer or solvent boil-off composites, 4. Foam rigidization, 5. Second order transition change and SMP composites, 6.Inflation gas reaction composites, 7. Aluminum and film laminates. The first 4 of those mechanisms are used in the “building” industry or other civil applications, the others might be considered too specific and expensive for this purpose. The research will be limited to polymer composites of the first 4 mechanisms.

This research is design oriented, and consists of a literature review, case studies and experimental research. It is an explorative study into the coherence and relation between:• topology of optimized structures,

• inflatable structures and

• rigidizing materials.

The variables of the above components are compared and ranked in matrices. The most promising combinations are used in the designs for beam structures, which have been realized and tested in prototypes and full-scale models.

Acknowledgements

We thank Carpro and our collages at the van Mussenbroek laboratory for their support with the realization and test of prototypes and full-scale models.

Structural Membranes 2013

Producing optimized structures with inflatables

In this paper we describe the research of the best combination of construction, material and typology for structures with bending moments constructed with fabric formwork. The results are inflated three dimensional (open cell) structures rigidized and structurally optimized. The structure is 40% lighter as conventional beams of the same material and was realized and tested in prototypes and full scale models.

Altair Technology Conference 2013

Rigidized inflatable structures

A production method for optimized structures using rigidized inflatables

A reduction of material use in construction is deemed essential for achieving a resource efficient Europe1,2. One of the most promising solutions, made possible by the emergence of generative design, is the use of structural optimization, which can lead to a weight reduction of 40% while maintaining stiffness properties. However, current production methods and processes are not adequately equipped for producing elements whose shape is derived from a structural optimization analysis3. Due to its nature to conform to funicular shapes, a production method based on inflatable moulds which are subsequently rigidized, is believed to be a promising solution. The purpose of this paper is to identify the morphological features of structurally optimized elements and which typology of inflatable structures best reflects them. In addition, rigidizable materials are explored to counteract the weaknesses of inflatable structures. This empirical scientific research is design oriented, and consists of a literature review and experimental research. In addition, to gain feedback on results, expert meetings were conducted. It is an explorative study into the coherence and relations between the characteristics of structural optimization, inflatable structures and rigidizable materials. The morphological features of section active structure systems4 were exposed using Solidthinking Inspire 9.0. Subsequently, for validation purposes, the ParaGen method developed by Dr.-Ing Peter von Buelow at the University of Michigan was used. Simultaneously, in depth literature reviews revealed the requirements, typologies and materials of inflatable structures and rigidizable materials. Ultimately, by comparing and ranking the variables from an optimization and production viewpoint, a tool that aids in developing a production method for structurally optimized elements based on rigidized inflatable structures is proposed.

Research Methodology

Domotica in seniorenhuisvesting in 2020

For the course Research Methodology the assignment was to write a paper or presentation about Domotica for the elderly in the year 2020. For this course a solid research is of great importance. At first your start with a mindmap and theoretical framework. After this a research model is made and the search for relevant papers is started.

With a chart the relevant papers are ranked by subject and importance. These charts are based on trends and state of the art. If all of this is worked out properly, scenario's for the future can be sketched, based on the know trends and state of the art.

The reseach is brought to the supervisors by a movie and a report.

Technology Transfer

Transferring the concept of interlocking puzzles to construction joints

Construction joints often demand a large quantity and diversity of materials for their connections. These connection materials are often in sight, while they are often not intended to be in sight. This paper contains an overview of existing joint construction techniques and applications, and introduces a method wherein connection materials are no longer necessary to apply; it makes a technology transfer from mechanical interlocking puzzles to construction joints. The connection method of interlocking puzzles can make a useful contribution in designing smooth construction joints wherein the overflow of materials flows smoothly and wherein connection materials become superfluous. By doing so, the aesthetic value of buildings can no longer be affected by connection materials. In addition, the method might lead to a more efficient use of material and to an increased building speed. In the paper, various mechanical puzzles are discussed in order to be able to select the best suitable options for construction and to display the added value of the new method.

Files

Report: Domotica in seniorenhuisvesting in 2020

Paper: Transferring the concept of interlocking puzzles to construction joints